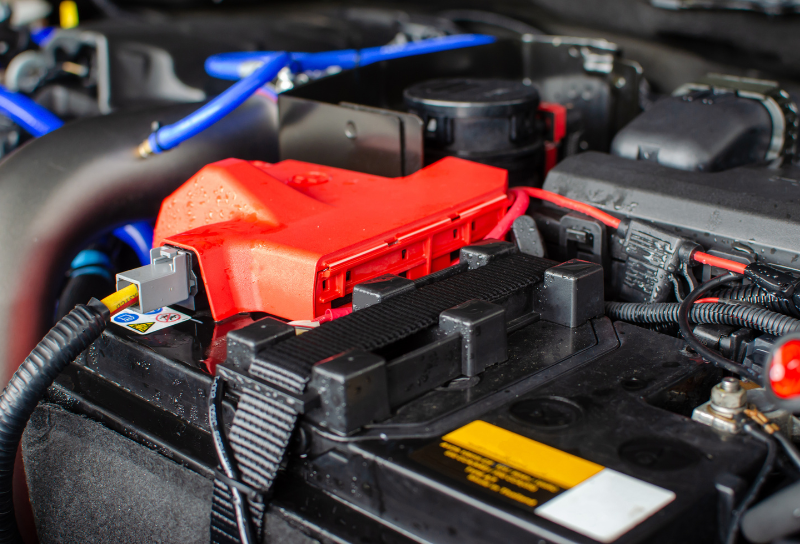

Battery Manufacturing

The largest global battery is the lead-acid type, used in various applications like automotive, backup power, and renewable energy storage. However, it has limitations, including low energy density, sensitivity to overcharging, and environmental concerns due to lead content. With the shift away from centralised power, we require reliable and powerful batteries. Battery manufacturing is complex, with many past efforts to improve energy storage and safety.

What did our client do?

Our client’s aim was to develop safe, environmentally and affordable energy storage solutions, ready for market. They achieved this with the development of a bipolar battery design that is 35% to 50% lighter than traditional lead batteries. 95% of their battery’s materials could be recycled and it had lowered carbon emissions than the traditional battery. To get to this fantastic discovery of the design, they had extensive research and experimentation into soldering current-collector plates, electroplating, lead metal disposition, active material pasting, and much more, using brand new methodologies, machinery, and strategies that have never been seen before in battery manufacturing.

How did we help?

The work of our client involved extensive research and the element of uncertainty which is central to R&D tax credit eligibility. Our specialist team worked closely with our client to understand their processes in designing the battery model so they could identify all R&D activity. Essentially, tracking how they made their discovery with all costs documented. We crafted the technical narrative, meeting HMRC’s exact standards, and communicated with HMRC on our client’s behalf. The process was streamlined and ensured our client received every penny they were entitled to from their determined efforts. The incredible financial benefit our client received from the R&D initiative has supported them to mass produce their product ready for commercialisation. This is a testimony of the unmissable opportunity of R&D; it supercharges the progress of innovation.